Indirect Solar Dryers

Synergy Solar, a leading supplier and installer of solar drying systems, has played a key role in delivering sustainable solutions to farms and businesses. Indirect solar dryers offer an energy-efficient method for drying agricultural products, textiles, and other moisture-sensitive materials. This comprehensive guide delves into the mechanics of indirect solar dryers, their benefits, and real-world applications across various industries.

What is an Indirect Solar Dryer?

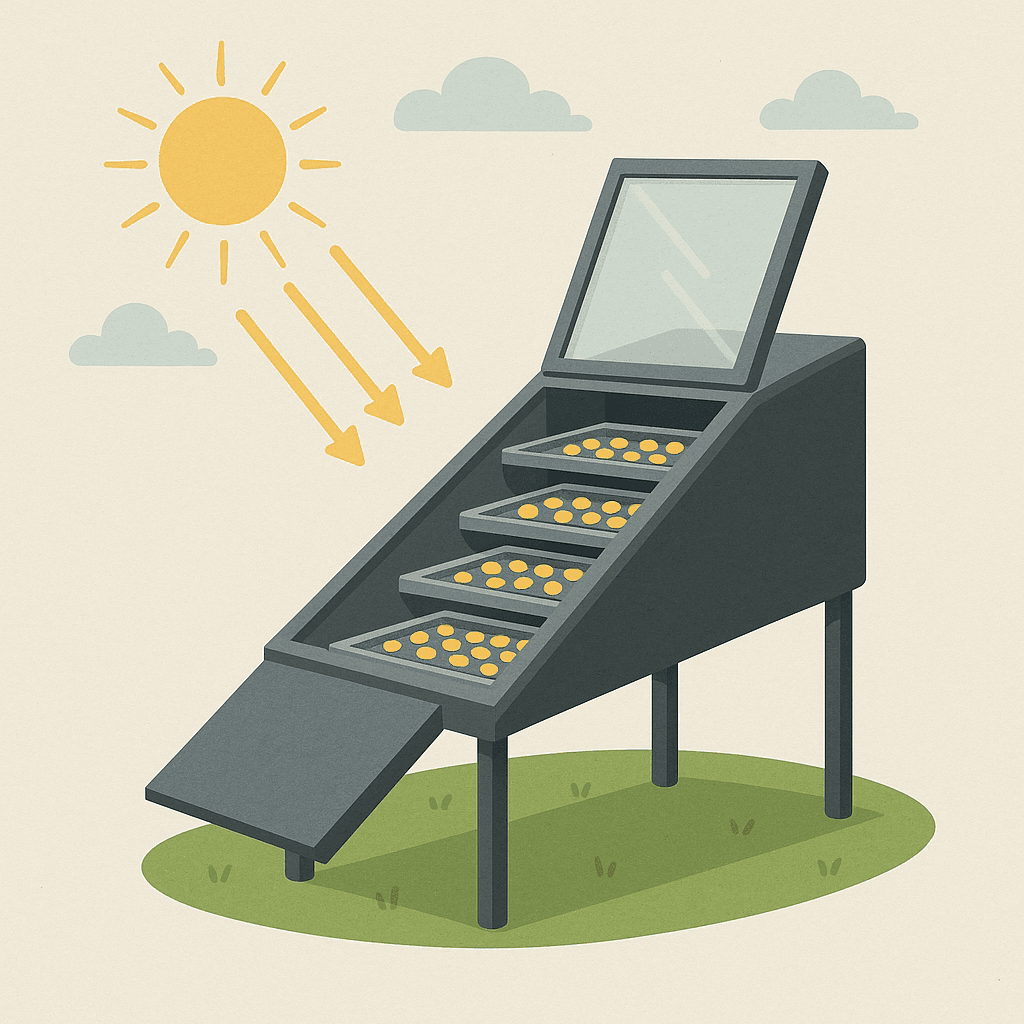

An indirect solar dryer is a solar drying system in which sunlight heats air first, and then the hot air passes over the product inside a separate drying chamber. Unlike direct solar dryers, the product is not exposed to direct sunlight. This helps protect the material from UV damage, preserves product quality, and supports better retention of color, flavor, and nutritional value.

Indirect solar dryers work mainly by convection. The solar collector heats the air, and that heated air is then circulated through the drying chamber to remove moisture from the product. This method is widely used for fruits, vegetables, herbs, spices, seeds, flowers, and other agricultural products that need cleaner and more controlled drying.

How Does an Indirect Solar Dryer Work?

Solar Collector

This essential component captures sunlight and converts it into heat, typically using advanced flat-plate or evacuated tube collectors known for their efficiency and durability. Our systems are designed with high-performance collectors that have been tested in various climates, ensuring reliability and effectiveness.

Heat Transfer Medium

Heated air is transported from the collector to the drying chamber through high-efficiency fans or natural convection, ensuring optimal airflow and temperature control. This precision is critical for maintaining product integrity, as our clients have experienced with their sensitive materials.

Drying Chamber

Inside the drying chamber, heated air circulates around the products, effectively absorbing moisture and facilitating the drying process. This design minimizes the risk of spoilage and maintains product integrity, which is crucial for businesses that prioritize quality. Our installations have demonstrated a marked improvement in product quality, as reported by numerous satisfied customers.

Exhaust System

An efficient exhaust system expels moist air from the drying chamber, allowing for continuous operation and preventing humidity buildup that could hinder the drying process. Our designs ensure smooth operation, even in high-humidity environments, making them ideal for diverse geographical locations.

Applications of Indirect Solar Dryers

Agricultural Products

Indirect solar dryers are extensively used in agriculture for drying fruits, vegetables, and herbs. They are ideal for sun-drying tomatoes, apples, and spices, preserving their flavor and nutritional value while minimizing spoilage. Our partnerships with agricultural cooperatives have highlighted the significant benefits of adopting solar drying technologies, leading to increased efficiency and profitability. Synergy Solar has supported farmers and cooperatives with tailored dryer installations that improve post-harvest management and reduce losses.

Food Processing

Food processing industries utilize indirect solar dryers to produce dried snacks and ingredients, ensuring that products like nuts and seeds retain their healthy oils and nutrients. This not only enhances product quality but also meets consumer demand for healthy options. Our clients have seen increased sales and customer satisfaction due to improved product offerings, solidifying their market position.

Textile Industry

In the textile sector, indirect solar dryers are employed to dry fabrics and garments, preventing shrinkage and maintaining material quality. This method is increasingly being adopted by eco-conscious manufacturers looking to reduce their carbon footprint. Our collaborations with textile manufacturers demonstrate how solar drying can enhance sustainability efforts and improve production timelines.

Pharmaceuticals

The pharmaceutical industry benefits from indirect solar dryers for drying herbal extracts and sensitive materials, where precise temperature control is crucial for preserving efficacy. This application underscores the technology’s importance in maintaining product integrity in critical sectors. Our expertise in pharmaceutical applications has positioned us as a trusted partner in this field, with numerous successful projects that enhance product reliability. Synergy Solar has installed dryers in compliance with strict industry requirements, ensuring consistent results.

Types of Indirect Solar Dryers

Batch Dryers

Ideal for small-scale operations, these dryers handle specific quantities of products at a time, making them perfect for local farmers or small businesses. We have collaborated with numerous small-scale producers to optimize their drying processes, resulting in enhanced efficiency and product quality.

Continuous Dryers

Designed for larger operations, these systems allow for a continuous flow of materials, enhancing efficiency and throughput for industrial applications. Our continuous dryers have been successfully implemented in several manufacturing facilities, yielding significant productivity gains and cost savings.

Hybrid Systems

These innovative systems combine solar power with other energy sources, ensuring consistent drying even on cloudy days. Our hybrid solutions have been recognized for their reliability and efficiency, even in less-than-ideal weather conditions, providing peace of mind to our clients.

Types of Indirect Solar Dryers

| Dryer Type | Description | Best Suited For | Common Applications |

| Batch Indirect Dryer | Handles fixed quantities per cycle; simple design and cost-effective | Small farmers, cooperatives, local producers | Herbs, spices, fruits, vegetables in small volumes |

| Continuous Indirect Dryer | Allows continuous material flow; high throughput; automated controls | Medium to large-scale industries | Grains, nuts, seeds, large-scale food processing |

| Hybrid Indirect Dryer | Combines solar with auxiliary heating (biomass, electricity, gas) for reliability | Areas with inconsistent sunlight, industries needing 24/7 output | Pharmaceuticals, textiles, bulk drying in variable climates |

Benefits of Indirect Solar Dryers

Enhanced Product Quality

By eliminating direct sunlight exposure, indirect solar dryers help maintain the nutritional quality, color, and flavor of dried products. This is crucial for preserving the integrity of fruits, vegetables, and herbs, ensuring they meet high market standards. Our clients have reported improved product quality and marketability after switching to indirect solar drying, with many achieving premium pricing for their goods.

Energy Efficiency

Utilizing renewable solar energy, indirect solar dryers significantly reduce reliance on electricity or fossil fuels. Studies indicate that these systems can save up to 80% in energy costs compared to traditional electric dryers, making them a financially sound choice for businesses. Our installations have demonstrated these savings, with many clients achieving payback periods of just a few years, supported by detailed financial analyses.

Versatility

From agricultural products to textiles, indirect solar dryers can be adapted for a wide range of applications. Their versatility makes them suitable for various industries, including food processing and pharmaceuticals. We have successfully customized solutions for diverse sectors, ensuring optimal performance tailored to specific product requirements, enhancing our clients’ operational capabilities.

Reduced Contamination

With products shielded from environmental elements, there is a lower risk of contamination from dust, insects, or other external factors. This ensures cleaner and safer dried goods, which is particularly important in food and pharmaceutical sectors. Our systems comply with industry hygiene standards, providing peace of mind to our clients and helping them meet regulatory requirements.

Cost-Effective Operation

Subsidy Support for Solar Dryers

Subsidy support for solar dryers may be available through the Agricultural Engineering Department, depending on the state, the current scheme, and the beneficiary category. For Tamil Nadu, the current official department page lists 40% to 50% subsidy for small and marginal farmers, and women farmers for installation of solar drying units. Since subsidy structure can vary by scheme and location, applicants should check the latest eligibility and assistance details with the concerned department before applying.

Why Choose Us?

Proven Expertise

Over a decade of successful solar dryer projects across agriculture, food processing, textiles, and pharmaceuticals.

Custom Solutions

Each dryer system is designed and installed to match local climate, product type, and operational scale.

Advanced Technology

High-performance solar collectors, durable drying chambers, and efficient exhaust systems built to last.

Turnkey Service

From consultation to installation, training, and after-sales support, we provide complete end-to-end service.

Hygiene & Compliance

All systems meet food-grade safety and pharmaceutical drying standards, ensuring quality and regulatory compliance.

FAQs about Indirect Solar Dryers

What is the difference between direct and indirect solar dryers?

Direct solar dryers expose products directly to sunlight, which can degrade color and quality. In contrast, indirect solar dryers heat air separately, preventing direct exposure and preserving product integrity, making them a superior choice for sensitive materials.

How much energy can an indirect solar dryer save?

On average, indirect solar dryers can save up to 80% in energy costs compared to traditional electric dryers, depending on design and local solar conditions. This significant reduction can lead to substantial savings over time, as evidenced by our client success stories.

What types of products can be dried using an indirect solar dryer?

Indirect solar dryers are versatile and can dry a wide range of products, including fruits, vegetables, grains, herbs, textiles, and pharmaceuticals. Their adaptability makes them suitable for various industries and applications.

Is it possible to use an indirect solar dryer in cloudy weather?

Yes, many indirect solar dryers are designed with hybrid systems that allow them to operate using alternative energy sources when solar energy is insufficient, ensuring consistent performance regardless of weather conditions.

How long does the drying process take with an indirect solar dryer?

Drying time varies based on the type of product, humidity levels, and the specific design of the dryer. Typically, it can range from a few hours to several days, with many users reporting efficient drying cycles that meet their production schedules.